Aviation Manufacturer

Rugged Mobile Devices Enable Aircraft Manufacturer To Meet Safety And Quality Targets

When a leading global aerospace manufacturer needed to upgrade their technology portfolio, they knew they must find a solution that would enable them to keep up with a high-volume production schedule, ensure the safety of their workers and help them deliver one of the most technically complex products imaginable – one tasked with safely carrying millions of passengers around the globe.

Luckily, this aerospace market leader already had a longstanding partner in Panasonic, enterprise grade mobile devices they had relied on for more than 15 years to help them design, build and maintain thousands of aircraft, supplying corporations and governments around the world that expect only the highest build quality. With that existing strategic partnership in mind, the company approached Panasonic to help them improve their production process, find new efficiencies and ensure that important data is collected, updated and made readily available to the employees who need it most.

Challenges

A major manufacturer of commercial airplanes was in need of a technology solution that helped them meet the demands of high-volume precision production while ensuring the highest levels of quality. They knew the workers at their facilities needed access to technology solutions that equaled the safety, efficiency and precision found in the jets they manufacture.

Solutions

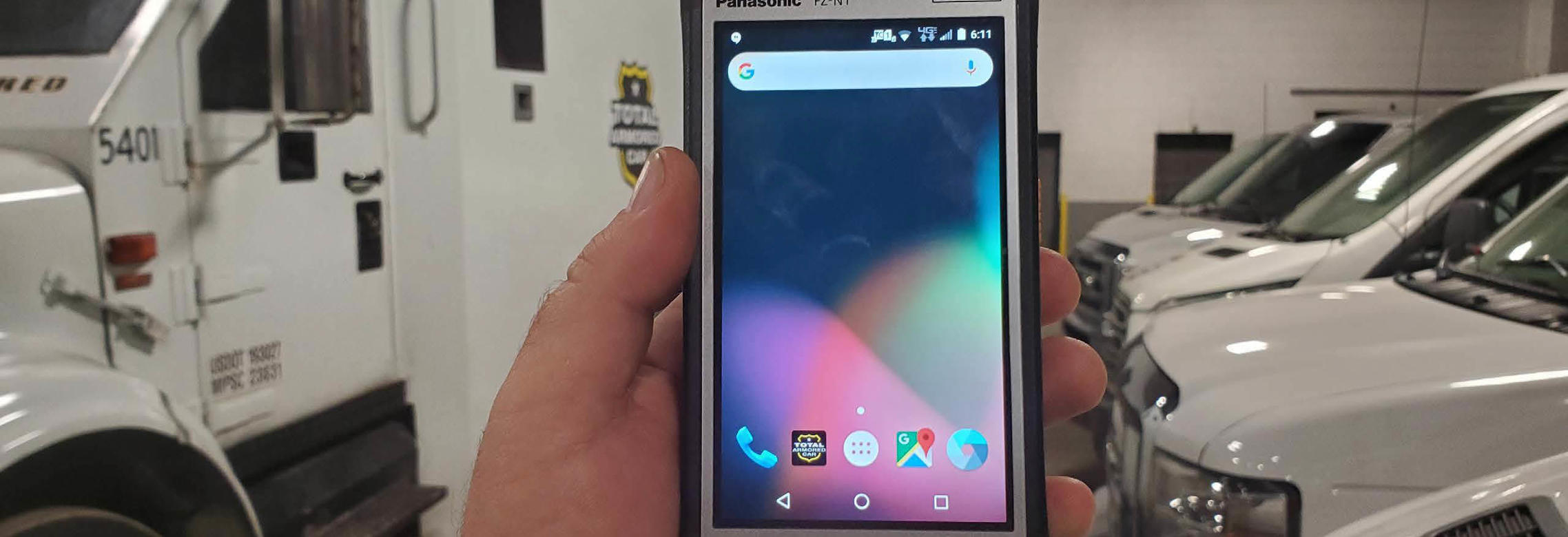

Having begun a relationship with Panasonic 15 years earlier and familiar with the TOUGHBOOK line of rugged mobile computers, the manufacturer deployed TOUGHPAD semi-rugged tablets throughout their facilities, looking to its long battery life and superior connectivity to meet the demands of this unique industrial environment.

Results

With a lightweight, ergonomic design, employees found themselves able to use the devices longer and more efficiently, making it easier for them to focus on the complex work of aerospace manufacturing. First-hand entry and electronic data capture led to better record keeping, helping ensure compliance in a highly regulated industry.

This choice was largely guided by the unique demands of the aerospace industry. As one of the most heavily regulated industries in the United States, aerospace manufacturers are well aware that they must not only be reliable from a business perspective, they must also account for the human lives that count on their steadfast dependability. To deliver on that promise, they knew they needed a solution as reliable, precise and designed for safety as the multimillion dollar aircraft that rolled off their assembly lines.

With these concerns in mind, and knowing they needed an agile, portable solution that could survive the demanding environment of an aircraft manufacturing facility, the company chose to deploy a fleet of Panasonic TOUGHBOOK tablets.

In the TOUGHBOOK semi-rugged tablets, this manufacturer found a device up to the task of supporting extended factory shifts and maintaining connectivity throughout long-distance walkthroughs. The larger screen size and lightweight design cut down on user fatigue while improving task efficiencies and decision-making across departments. And with first-hand entry and electronic data capture, the TOUGHBOOK tablets – complete with the company’s customized mobile application – have improved documentation by completely cutting out pen and paper for tracking activities and reviewing customer deliveries, helping to ensure compliance with industry standards.

The choice to deploy these durable tablets across their manufacturing facilities is a testament to the strong relationship Panasonic has with its customers. Since this aerospace leader adopted the original TOUGHBOOK laptops in 2000, they have remained loyal to Panasonic because of their shared commitments to consistency, integrity and the unceasing desire to innovate.